Great science. Innovative thinking. More progress, faster.

Creating solutions when traditional methods fail.

This typically includes the following steps:

- Analysis of the physical system to determine what biorelevant measurables are needed and model processes that may occur

- Experimental design to obtain the metrics

- Data analysis and interpretation to derive results that can be utilized in formulation science and/or regulatory interactions

Complex dosage form evaluation

- Design, bioequivalence, QA

- Ophthalmic products

- Physiologically relevant in vitro release testing (dissolution/release)

- Drug distribution

- Complex injectables—drug-protein complexes

- Drug release and distribution

- Manufacturing optimization

- Develop QA tests for ophthalmics and other complex dosage forms

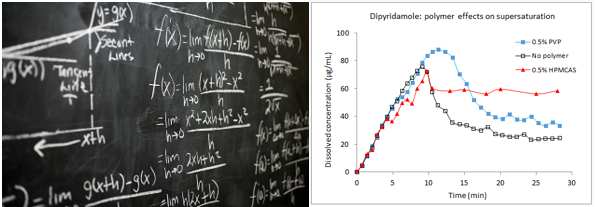

supersaturating formulations

- Supersaturating oral dosage forms to measure the absorbable dissolved concentration profile

- Screen for excipients that provide optimal bioavailability – can be done in any medium to predict performance in the GI fluids

- Applications include:

- Polymer screening for amorphous solid dispersions

- Nanoparticle delivery systems

- Neat amorphous API

- Lipid systems

Problem analysis

- Complex formulation physical modeling and analysis

- Ophthalmic products

- Drug-protein injectables

- Amorphous supersaturating formulations

- Data generation for product development & regulatory evaluation

- Dosage form in vitro and biopharmaceutical analysis to identify critical parameters

- Experimental method development

Biorelevant In vitro dissolution/release tests

- Customized release test development

- Ophthalmic, intranasal, and injectable formulations

- Supersaturated media precipitation/crystallization rates

- Release from semi-solid formulations

Dosage design for poorly soluble drugs

- Determine target absorption from pharmacokinetic data

- Design target in vitro dissolution to optimize bioavailability

- Solubilization formulation strategies and testing

- Drug-protein/polymer binding and release kinetics

Alliances and Business opportunities

- Ophthalmic and nasal products in the pipeline- ANDAs and NDAs

- Developing manufacturing technologies for amorphous solid dispersions (patents pending)

- Marketing partners

- Work with pharma companies developing ANDAs and NDAs